The ClubTurf ‘Natural’ Pitch |

|

|

The ClubTurf ‘Natural’ Pitch is designed to closely replicate the playing characteristics of a well prepared natural turf pitch. The sub-base is constructed entirely of natural materials and offers the full range of weather-affected changeable playing characteristics. Provided the pitch is cared for and receives sufficient Routine Maintenance, its changeability will always be predictable with never the erratic performance of a poor natural turf pitch. The ClubTurf playing surface is designed to support both spin and seam bowlers, although as Derek Underwood points out, “It offers a fair reward for skills whether batter or bowler and, although favouring the batsman by virtue of its predictability, the bowler who can extract whatever may be in the pitch will get his wickets." A non-turf pitch can not be used in all weather and is not maintenance free, however it scores over a natural turf pitch because it can be used continuously throughout the season without any loss of performance, provided routine maintenance is carried out. In addition to periodic treatments for weeds, moss, algae and worms, a non-turf pitch needs to be regularly swept clear of debris and rolled with a light roller (250kg – 350kg) to keep the base flat. We recommend 30 minutes of sweeping and rolling for every 10 hours of use for a ClubTurf ‘Natural’ Pitch. Over time the base may start to show signs of wear, particularly in the bowler’s footmarks and the block holes. We recommend that we carry out a Periodic Maintenance every three years to service the base and re-fit the playing surface. For budgeting purposes you should allow between 1% and 2% of the total cost of the facility per year for Periodic Maintenances. |

|

|

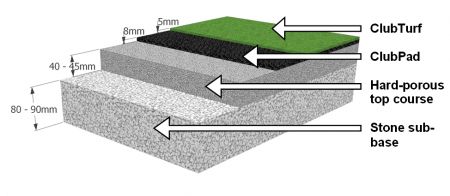

Detailed Specification: Surface: 5mm. +/- 1mm. Wilton woven ClubTurf Pile: 700g/m2 100% UVS Polypropylene Backing: UVS Polypropylene with vinyl ethylene resin (EVA) Total Weight: 1540g/m2 Layer 1: Bowlers’ Run-ups and Popping creases only Layer 2: 40-45mm depth angular unbound mineral (hard-porous) Layer 3: 80-90mm depth angular stone |

Construction Characteristics: Woven synthetic turf surface laid on unbound mineral material (hard-porous) and a stone base. A porous rubber shock pad (ClubPad) is laid between the ClubTurf surface and the hard-porous top course in the bowler’s run-ups and through the popping crease. |

|

|

ClubTurf | ClubTurf Cricket Limited

Northern Office: 01270 753344

Southern Office: 01892 837598